During the life of field there will be a need for removal of templates, jackets, wells or other structures which are piled to the seabed. To remove these structures, the piles need to be cut.

There are various national regulations and guidelines for how far below seabed a pile/well must be cut to permanent abandon the field. For example, Petroleumstilsynet in Norway states that piles must be cut below seabed, without stating the required depth. In the Netherlands on the other hand the common cutting depth is six meters below seabed. Selection of the best cutting method is an advanced exercise based on experience, if the cuts are on a critical line or not, where the cut is to be made and sometimes also if there are access in- or outside the piles. In the following we will go through some of these evaluations and try to shed some light on the process and evaluations done prior to selecting cutting method.

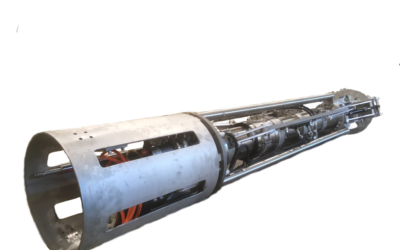

Image Caption: Internal cutting tool.

Internal Cutting tool

There are several cutting methods to choose from. Abrasive water jet cutting (can be done internal and external), diamond wire cutting (mostly external) mechanical cutting, subsea torches, laser cutting and more. In this article we will focus on the difference between abrasive cutting and diamond wire cutting. These methods are the two most common cutting methods with longest track record for pile separation and are the two most preferred methods for operators and contractors within the decommissioning industry.

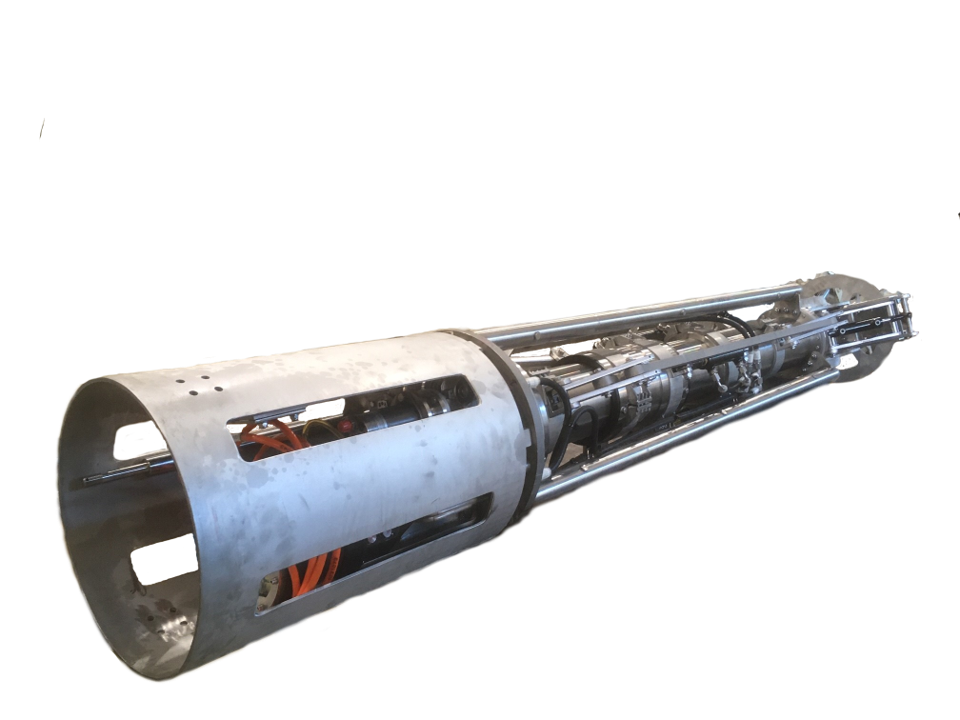

Image Caption: External Abrasive Cutting Tool

External Abrasive Cutting Tool

As a rule of thumb abrasive cutting is up to three times faster than diamond wire cutting. On the other hand, the abrasive cutting spread is more expensive to mobilize and demands more skilled and experienced personnel and also increased POB (personnel on board). There are advantages and disadvantages for both cutting methods and some critical points to consider are:

- Is cutting on the critical line?

- Is there internal access in the pile?

- Is there external access to the pile?

- Required cutting depth below seabed?

- Duration for dredging around the pile to required cutting depth?

- Durations for removing soil plug or obstacles inside the pile?

- One cut or several cuts?

- Water depth?

- Available ROVs/divers?

- Deck space?

- High-tolerance cut finish or rough cut?

- Is cold cutting required?

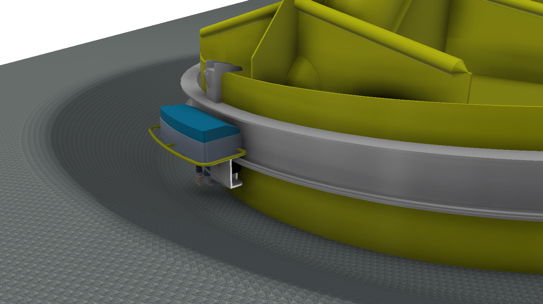

Image Caption: Diamond Wire Saw

Diamond Wire Saw

Sometimes you might not have internal access and need to eliminate internal cutting as an option. Even in these cases you have not dismissed abrasive cutting as a method. In many cases you can install a track around the leg and have a trolley travel 360 degrees and cut the pile with abrasive cutting technology. You can also install a diamond wire saw on the same pile and cut with the diamond wire cutting technology. If speed, criticality and there is a lot of material to cut at a relatively favourable water depth (7-800 meters or shallower) external water abrasive cutting method can be the best.

On the other hand, diamond wire cutting method might be favourable if you have less deck space, can do the cut with standard saws and can allow for longer cut durations. Pile size and deployment and installation is also critical points to consider.

Selecting the best cutting method is an advanced exercise where several factors needs to be accounted for. Selecting the correct method is done based on experience, calculations, project specific parameters and physical restrictions and site. It can be of high value for the project total cost to evaluate different cutting methods and include cutting specialists before concluding on cutting method and contingencies.