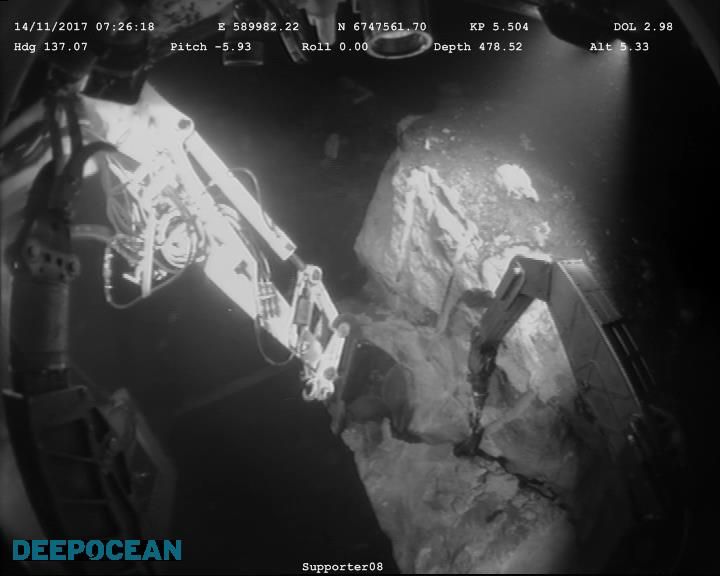

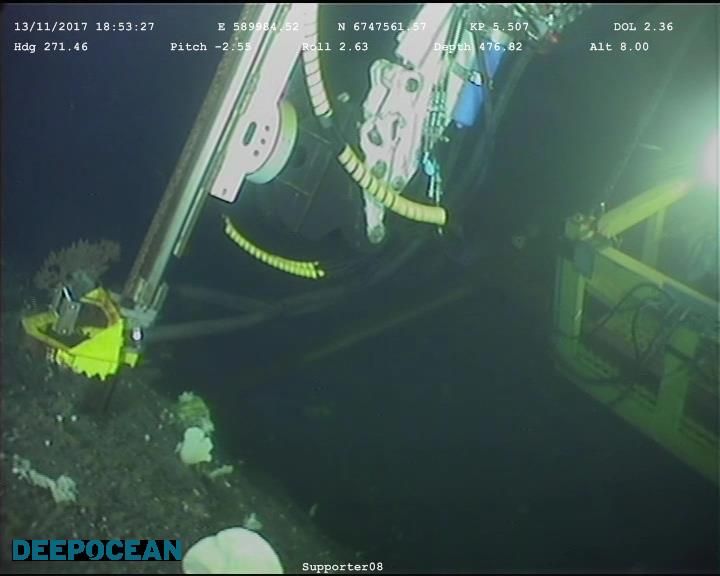

Once again, Scanmudring proved that the adaption of known and tested onshore equipment can be transferred to subsea remote operations with great success!

Deep water rock formations have traditionally been avoided during pipeline route selection instead of being modified to allow for safe pipeline installation. This is mainly due to lack of proven tools for deep-water rock removal and/or due to high costs for the operation. For the deep-water challenges on the Johan Sverdrup project the use of conventional drill and blast methods was investigated but found to represent a too high risk. This was because of the proximity to existing live pipelines in the fjord and no reference to any previous rock removal, using drilling nor blasting at this water depth. Scanmudring was approached by Equinor to perform a feasibility study for the rock removal required at the landfall tunnel exit area outside Mongstad to allow for a safe pull-in of Johan Sverdrup oil pipeline. The feasibility study evaluated a wide range of available tools for subsea rock removing, all tools suitable of being mounted on a Scanmachine.

In conjunction with the 2019 ISOPE conference, Scanmudring prepared an article in collaboration with Equinor and DeepOcean which presented the background, the introduction of a variety of new tools and the offshore execution campaign.

To view full article – See more