Image Caption: Picture from onshore testing of new grab

Planning Phase

In the planning phase we went through the scope of work to highlight project specific challenges. Based on the large volume, the conclusion was that a traditional ejector setup was not ideal as main tool on this project. The adaption of known and tested onshore equipment had been transferred to subsea remote operations with great success in the past, and so was the case this time. A 2m3 grab was acquired and tested onshore prior to the offshore execution.

Working with low visibility and hide tide, meant that we had to put in extra initiative to monitor the operation and an echoscope software was brought offshore in addition to the excavator’s existing monitoring system.

Challenges

- High tide currents

- Low visibility

- Lack of ROV support

- Precise placement of rock dump

- Minimize disturbance to surrounding area

- How to maximize efficiency in execution of SOW

Specific Tooling

The new developed Scanmachine 40Te with the capacity to mount a 2m3 grab

- High production as well as high precision on placement of material

- No need for hose handling

- Less support from ROV needed

- Works within the given tolerances of +-300mm

- Commonly used excavation tool onshore

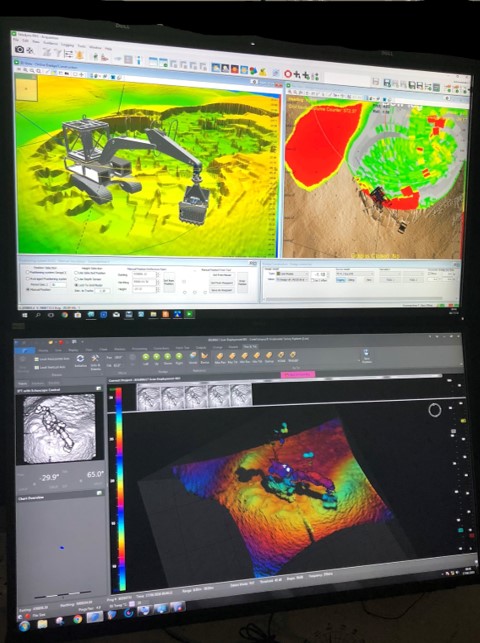

Image Caption: Top screen showing the 3D software of the excavator and bottom screen showing the exchoscope software

Project Execution

Excavation with 2m3 grab

Project started the with the 2m3 grab.

- The 3D sonar was the main “camera” and in combination with the 3D modelling software good progress was reported right from the start.

- Estimated performance based on simulations from planning phase at 48m3/h

- Measured performance during execution at 55m3/h

Excavation with bucket

- The final levelling and some parts of the scope had to be done with bucket.

- Estimated performance based on simulations from planning phase at 20m3/h

- Measured performance between 17-28m3/h depending on bulk relocation or levelling of top surface.

Image Caption: Picture of 40Te excavator with bucket

Conclusion / Lessons Learned

- Project executed is a safe and effective matter

- Good project planning together with contractor, big part of the success.

- Tidal conditions led to bad visibility and narrow dive window for ROV. Coda echoscope was heavily relied on.

- Work at the Viking field is limited for ROV due to tidal conditions, ie Survey, inspections, support and monitoring in operation.

- Use of live sonar imagine is ideal at this depth

- 2m3 grab effective in fine rock material