Image Caption: Picture from onshore testing of Log grapple and 2m Tilt bucket

Planning Phase

Project specific challenges were highlighted in the planning phase. Based on the significant volume of mass to be processed, we had learned from the 2018 campaign that the grab setup proved to be more efficient than the traditional ejector setup. This time, to further improve the seabed preparation, a 2.1m levelling bucket with tilt was chosen as the main tool.

In addition, and on short time notice, the client requested if Scanmudring could come up with a tool that could pick up and relocate pipes from 3” to 20”. Scanmudring got hold of a traditional onshore log grapple which was modified and tested at the Scanmudring facilities.

To deal with the debris and potential hard material, a ripper tooth was also brought offshore.

Challenges

- High tide currents

- Low visibility

- Lack of ROV support

- Precise placement of rock dump

- Minimize disturbance to surrounding area

- Debris

- How to maximize efficiency in execution of SOW

Specific Tooling

Scanmachine 40Te with the capacity to mount heavy duty tooling

- High production as well as high precision on placement of material

- No need for hose handling

- Less support from ROV needed

- Works within the given tolerances of +-200mm

- Commonly used excavation tools from the onshore excavator partners

Image Caption: 40Te Scanmachine with 2.1 m levelling bucket with tilt

Image Caption: Ripper tooth

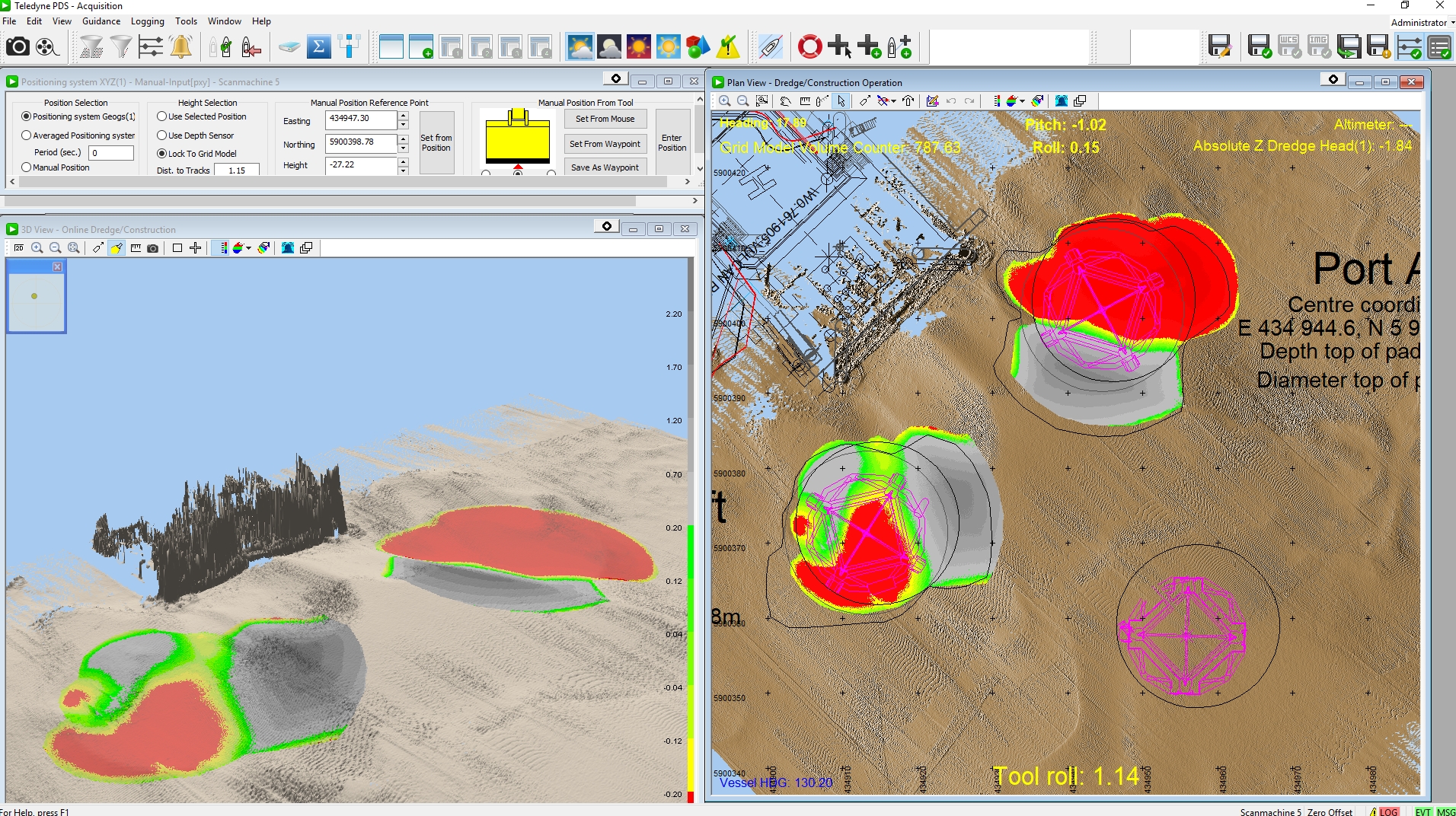

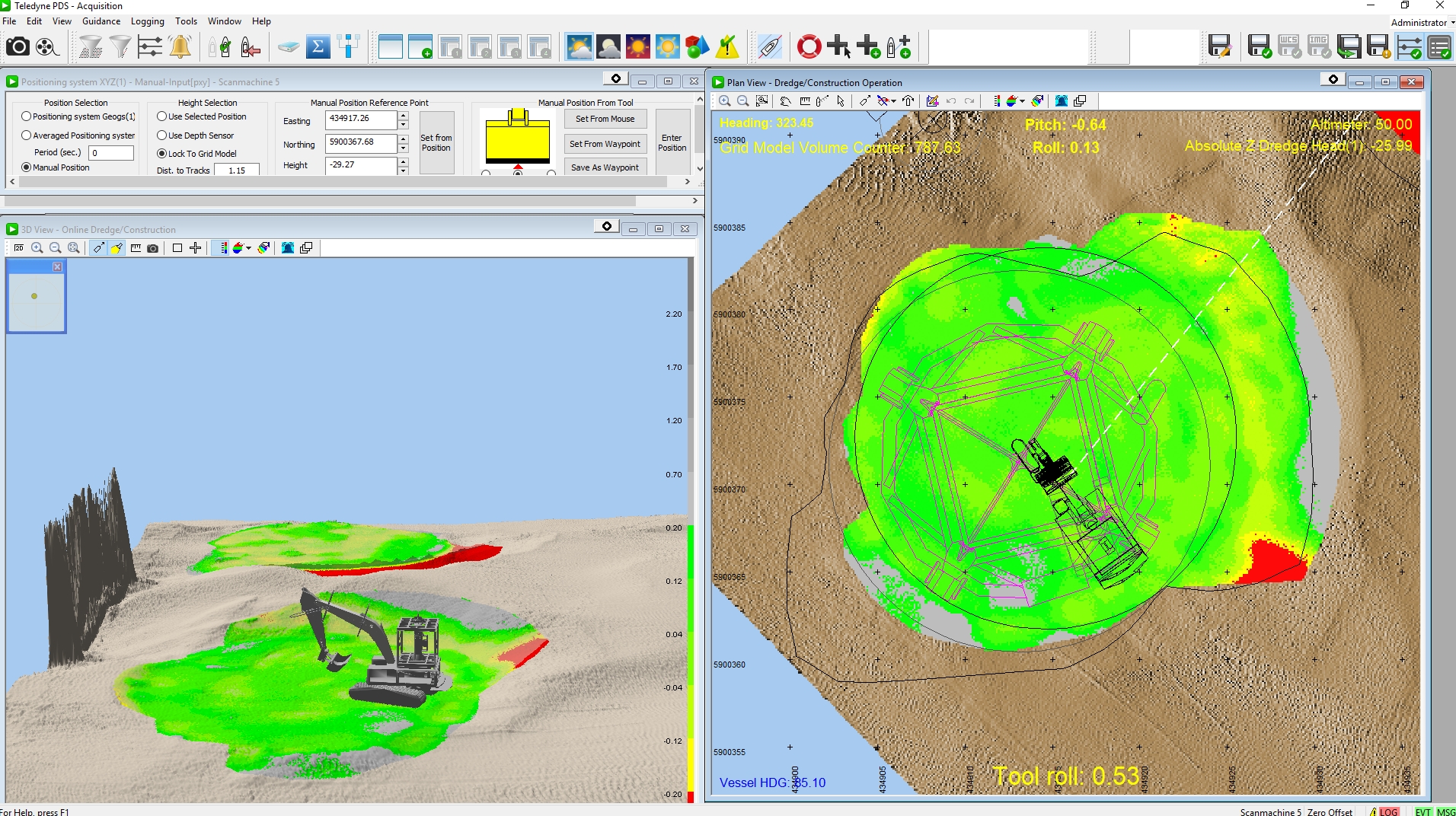

Project Execution

Execution of Pad remedial SOW

The fundamental of the proposed design was to reduce overall berm thickness and where necessary remove side walls and outer edges of top pad arrangements (scalloping), re-depositing the removed rock within the footprint of the proposed berm design.

The large Tilt bucket was utilized for the entire part of this SOW, which turned out to be very efficient. This mainly for the ability to hold the bucket level, regardless of machine roll – all monitored in PDS, and the thin and precise blade on the bucket.

Image Caption: 40Te Scanmachine with Log Grapple

Execution of Pipe uncovering and debri removal SOW

- The log grapple was utilized to manoeuvre pipes of different sizes inaccessible to the crane. This tool was able to lift and shift a 5-6m section of 20″ pipe a distance of 60-70m to desired area within a matter of minutes

- The ripper tooth was used to break through hard layers to reach the depth to where the pipe was located. This tool was also used to drag longer sections of pipes that were choked with softslings.

- Suction nozzle was the preferred method for uncovering various pipes and make room for future DWS cutting on some locations. This was mainly to ensure visibility.

Image Caption: Log Grapple picking up and relocating pipe subsea

Image Caption: Example – pre dredging

Conclusion / Lessons Learned

- Project was executed in a safe and effective matter

- Good project planning together with contractor, big part of the success.

- Depth reading setup can be challenging in shallow waters, with readings being affected by the waves. This can be improved for future campaigns

- The 40Te machine proved reliable with dives consisting of the continuing heavy excavation up to 87hours without issues

Image Caption: Example – post dredging