Remote underwater construction services for the civil market!

The oil and gas industry has for decades been focusing on replacing typically diver performed tasks with remote-controlled vehicles, driven by safety and efficiency benefits. Bringing our expertise from the offshore market, Scanmudring can offer a vast range of proven remote underwater construction services in all kinds of water depths and conditions.

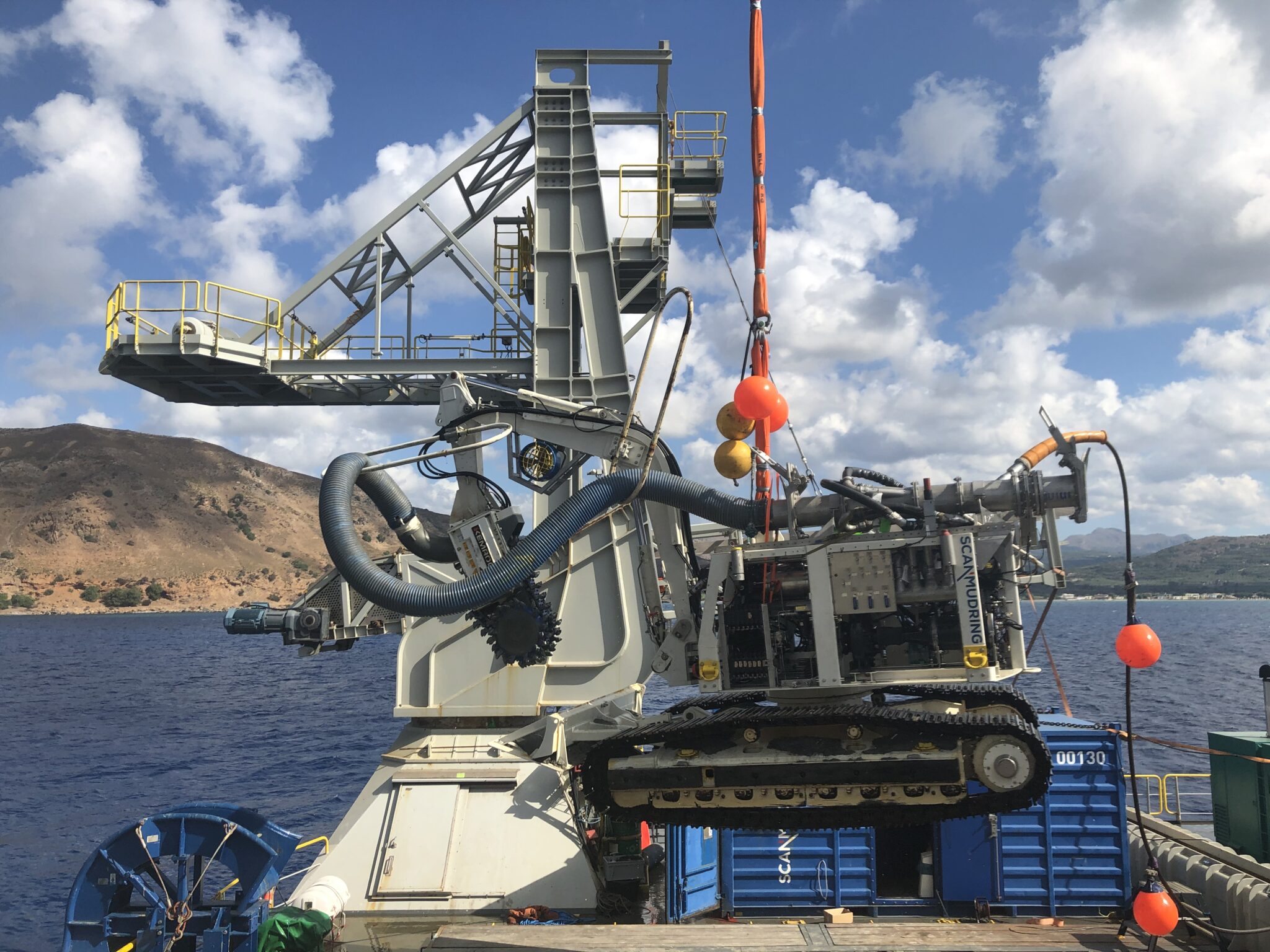

The infrastructure market is used to the characteristics of the land-based excavators, where also the Scanmudring subsea excavators, named Scanmachine, have their origin. This also includes a broad portfolio of land-based tools that have been configured and prepared for underwater operations.

Whether it’s underwater tunnel projects, coastal roads or other nearshore projects, our team is ready to get involved from the outset. We bring unique skills and experience to the planning of complex operations, providing a firm foundation for the optimum in the project’s safety, efficiency and success.

Before the selection of the anchoring method, Scanmudring may contribute in many ways based on our decades of experience in underwater construction work.

Remote and Precision Services

The Scanmudring services make traditional onshore methods possible in underwater environments.

Dredging

One of the most used configurations of our Scanmachine is dredging mode. In dredging mode, the machine is equipped with a pumping system¹, which is project depending based on material size², relocation distance³ and disposal method required4.

Examples of services:

- seabed preparations prior to installation of various gravity-based foundations

- Low turbidity removal of toxic sediments in a close system

- removal of built-up of sediments and debris inside underwater tunnels/pipelines, like in this project

- removal of built-up of sediments and debris inside or underneath quay facilities, ship lifts or buildings

- operations where mechanical excavation is not preferred due to damage to surface or assets, dredging methods could be used to ensure precision and controlled removal of material

- cable and pipe installation projects making trenches inshore approaches where traditional methods struggle due to water depth, current and waves

- cable and pipe installation projects making trenches in areas where traditional methods struggle due to hard or challenging seabed conditions

- ScanCrawler – sediment remediation

- Underneath a building by the Hudson River, NY.

- 20Te Scanmachine – underwater tunnel excavation in Berlin

- The most used pumping method is the ejector or slurry pump.

- We manage to pump material with the size range up to 350 mm without any pre-treatment. Larger or consolidated material is pre-treated by various excavator tools.

- Particles larger than 100 mm require an ejector system for transportation. This system is initially limited to a length of 150 m in water.

- Particles less than 100 mm can be transported to any length and above water. This can range from free spreading where turbidity and water volume do not have an impact on feeding into a treatment plant where water volume should be minimised.

Excavation

Regular excavation tools can equip the Scanmachine, i.e. bucket, grabs or levelling screed to perform traditional onshore excavator tasks underwater, like local relocation¹ of large-sized materials² and levelling³.

Examples:

- seabed preparations/ levelling prior to installation of various gravity-based foundations

- removal of large objects/ debris inside or underneath quay facilities, ship lifts or buildings

- cable and pipe installation projects making trenches inshore approaches where traditional methods struggle due to water depth, current and waves

- cable and pipe installation projects making trenches in areas where traditional methods struggle due to hard or challenging seabed conditions

- GBS levelling

- Route optimisation with grab

- The reach of the Scanmachine, which is depending on the size of Scanmachine and boom/dipper configuration, limits rapid relocation. In standard configurations, this is limited to 20m.

- Weight limits how much the Scanmachine can handle. Our largest Scanmachine is capable of lifting up to 16Te.

- Scanmachine is capable of levelling large areas in a highly efficient manner down to +/-2cm due to automation.

Removal or Shaping of Hard Materials

A broad range of tools to pre-treat¹ material or objects² before or in combination with dredging or excavation can equip the Scanmachine. Typically, pre-treatment in combination with dredging is ranging from ripper teeth on the suction nozzle to suction on drum cutter (see the latter is in the picture below).

Examples:

- removal/ shaping of grout, concrete and bedrock to remove or replace a large diameter drill rig

- crushing of consolidated material for dredging

- drilling in any direction for blasting

- drilling in any direction for pile installation (dimensions up to 500mm available)

- mechanical shears to cut

- Drilling

- Mechanical removal using ripper tooth

- To be able to transport the material, the material must be crushed down to smaller particles less than 350 mm for dredging.

- For dredging, the object needs to be less than 350mm and for excavation less than 16Te

Cutting Solutions

Scanmudring is the leading underwater cutting provider. The ability to deliver cost-efficient and safe equipment and flexible services, together with decades of experience with dedicated personnel with industry-leading experience, know-how and engineering capability, put Scanmudring in a unique position.

Scanmudring can offer abrasive cutting technology, consisting of high-pressure water mixed with sand to cut any structure in any shape. The speed of the water/sand mixture (called a slurry) exceeds hypersonic speed and is a powerful, proven and efficient method for cutting. Scanmudring abrasive cutting technology and mixing unit (SACS) is technological the most advanced abrasive cutting system on the market.

Diamond wire cutting is also a service Scanmudring offers. A diamond wire is used for cutting of steel, concrete, rock or other materials on both tubular and flat surfaces.

The cutting manipulator is operated remotely from a dedicated control container. During operation, only the cutting manipulator is present at the cut location with all personnel and dedicated installation vehicle on a safe distance.

All Scanmudring cutting solutions work both on land and in an underwater environment and can be installed by our Scanmachines, divers, ROV or in some cases directly by a crane.