Planning Phase

Once the substation jacket was installed, a rock dumping vessel performed the scour protection around the jacket, but there was still a need for rock installation inside the jacket.

Challenges

- Strong current & Low visibility

- Precise placement of rock dump, especially around the spudcans

- Limiting access inside the jacket – how to get inside with the equipment

- Minimize disturbance to the pre-installed filter layer

- How to maximize efficiency in execution of SOW

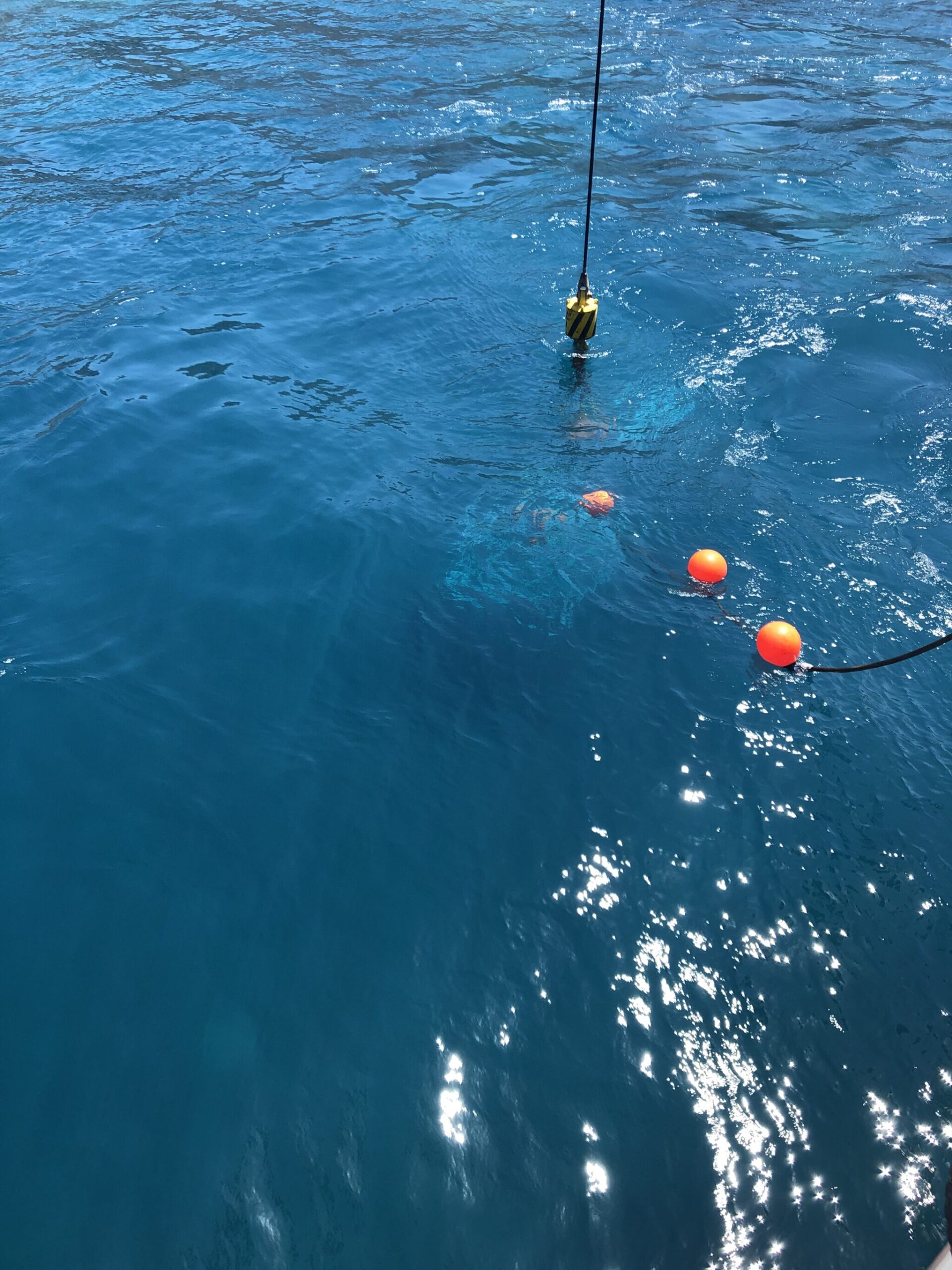

- The operation required solutions for monitoring of the operation as well as the ability of working stable independently of the tidal current.

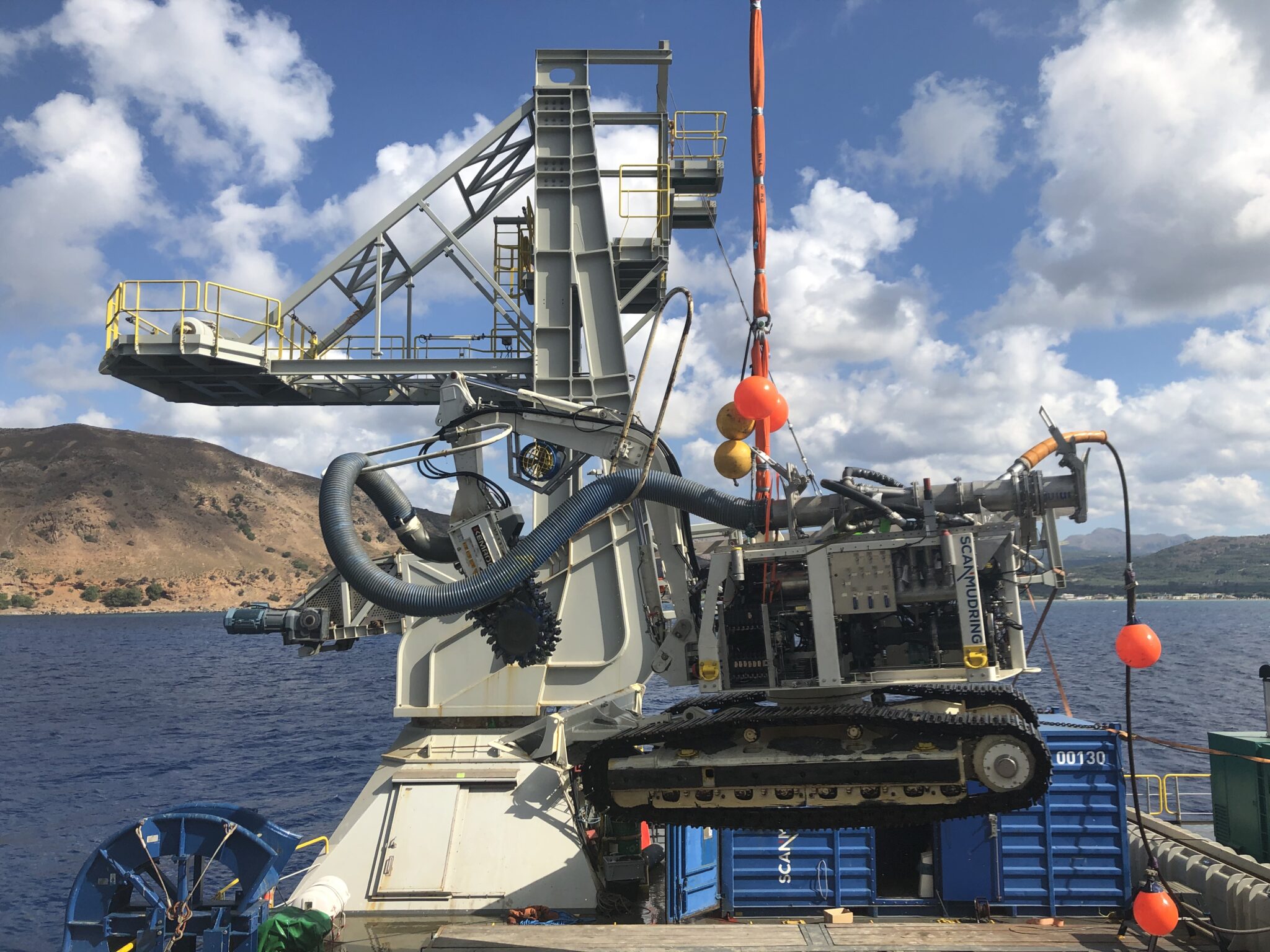

- The ScanCrawler had been utilized within structures in the past and was selected for placing the rock, whilst the 15Te Scanmachine was selected for feeding the Scancrawler with gravel pre-dumped outside the jacket.

Project Execution

SIMOPS utilizing both Scanmachine and Scancrawler

As the images show, the method statement was for the Scanmachine to work with the pre-dumped lumps of gravel, have the exhaust connected to the ScanCrawler working inside the structure and placing the rock dump.

Conclusion / Lessons Learned

- Project executed is a safe and effective matter

- Good project planning together with contractor, big part of the success.

- The rock size was larger than advised/ expected resulting in clogging

- As it was only possible to have one observation ROV and one work class ROV in the water, a lot of docking and un-docking was required of the Scancrawler. The ROVs did a good job, struggling in strong current, shallow water and difficult surroundings (inside jacket), but this slowed down the operation

- Relocating the whole spread with hose connected to both machines worked out good